Fasten Different Screws With Automatic Screw Locking Machine

time2019/07/25

- The best way to fasten things together is usually by means of screws. The other two common methods –nailing and soldering with automatic soldering machine are often quicker and require less preparatory work.

Fasten Different Screws With Automatic Screw Locking Machine

The best way to fasten things together is usually by means of screws. The other two common methods –nailing and soldering with automatic soldering machine are often quicker and require less preparatory work. Both methods produce permanent joints which cannot be easily dismantled again. None of the two methods has the ability to produce the abuse resistance and strength that screwed joints have.

Selecting the right screw for the job can be quite a complicated process as there are variations in head styles, materials, thread types, plated finishes, and sizes.

There are two basic head slot styles in addition to different head styles –

The traditional slotted-head style and

The so-called cross-head style.

There are three cross-head styles which unfortunately can be difficult to identify. Pozidriv –the most familiar one –is found mainly on wood screws. Supadriv head –the more recent one –is similar and can give better grip between the screw and screwdriver, though the difference is not significant in practice with wood screws.

The third style, known as Phillips, can be found mainly on self-tapping screws and machines fitted to products manufactured in the Far East and on the continent.

Traditional slotted-head screws can be turned by means of a single slot into which a screwdriver blade should fit closely. And because the screw varies with the slot size, a range of screwdrivers is required to cope with all the different sizes of screws that are likely to be used. In practice, the wrong size of screwdriver is often used; and if it is too small, the blade can easily ride out or slip out of the slot.

Cross-head screws have the advantage of ease of turning than conventional screws. And when it is impossible to make sure that the screwdriver blade and the screw head are exactly in line, they are easier to turn. The Pozidriv system has another advantage –that only three screwdriver points are required to cover all sizes of screw (the most common size is No. 2). The Pozidriv screwdrivers can also be used for Supadriv screws though Phillips screws require to have their own driver.

Cross-head screws usually have disadvantages when their slots get filled with paint (as usually is the case with door hinges) there is usually great difficulty when cleaning them out well enough to get the screwdriver blade in. In the case of a conventional slotted-head, it can easily be cleaned with a hacksaw blade or trimming knife.

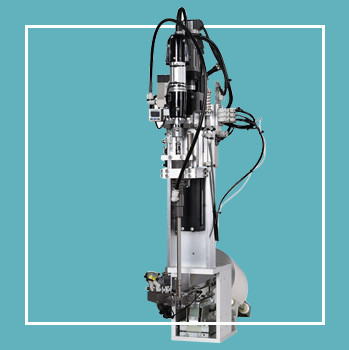

All of these screw types can be used in an automatic screw locking machine with an automatic screw feeder.

Many screws designed to be used for wood have a thread which extends about 60 per cent of the way from the tip to the head, thereby leaving a portion of shank which is blank and slightly thicker. Any screw which has threads extending over their full length should be closely examined. They may be either twin fast screws designed for use in chipboard or self-tapping screws designed for fastening metal but useful for general woodworking.